Our Capability

Raw Materials

The basic materials or components utilized in the first steps of manufacturing or production processes are known as raw materials. They are essential to industrial growth and economic development because they provide the framework for the production of completed items in a variety of industries. Comprehending the varieties, origins, and importance of raw materials is vital for enterprises seeking to maximize production effectiveness, caliber, and durability.

Modern industrial and manufacturing processes rely heavily on raw materials, which also have an impact on sustainability initiatives, economic growth, and technical advancements. For businesses to handle the complexities of a global supply chain and take advantage of new opportunities in a dynamic marketplace, they must take a strategic approach to the procurement, management, and production of raw materials.

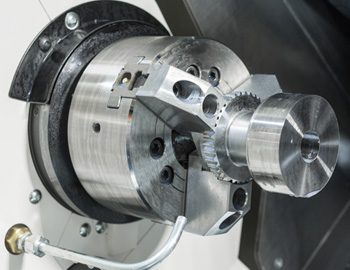

Various Materials we work on

- 1. Metals

- Aluminum

- Stainless Steel

- Brass

- Titanium

- Tool Steel

- Copper

- 2. Plastics

- ABS (Acrylonitrile Butadiene Styrene)

- Nylon

- Acrylic (PMMA)

- Polycarbonate

- PEEK (Polyether Ether Ketone)

Surface Treatments

Surface treatments are essential for improving the functionality, robustness, and visual appeal of CNC machined products. The quality and functionality of products can be enhanced by CNC manufacturing businesses through the application of certain coatings and finishes.

When it comes to maximizing the functionality, robustness, and visual appeal of CNC machined parts, surface treatments are essential. CNC manufacturing businesses may effectively distinguish their goods in the market, adhere to strict quality requirements, and improve customer satisfaction by utilizing appropriate surface treatment procedures.

Common Surface Treatments for CNC Machined Parts

- Anodizing

- Electroplating

- Powder Coating

- Chemical Conversion Coating

- Passivation

- Painting and Coating

- Hard Coating

- Electropolishing

- Shot Peening